产品特点:

整体焊接加工结构。

德国进口电液伺服阀及进口光栅尺构成的闭环控制方式,滑块位置反馈精度高,运行准确平稳,同步性能好,折弯精度、滑块的重复定位精度高。

后挡料可根据客户需求采用功能更为齐全的多个后挡料轴的后挡料机构。

液压系统采用集成式控制系统,减少了管路的安装,克服漏油现象,确保了机床的工作稳定性,外形简洁美观。

液压挠度自动补偿机构,消除了滑块变形对工件质量的影响,数控系统自动调整补偿量,方便准确。

数控系统采用荷兰DELEM、意大利ESA或瑞士CYBELEC电液伺服折弯机专用数控系统。

Product Features:

The overall welding processing structure.

The closed-loop control method composed of imported electro-hydraulic servo valves and imported grating rulers from Germany has high precision in slider position feedback, accurate and stable operation, good synchronization performance, high bending accuracy, and high repeatability of slider positioning.

The rear material blocking mechanism can adopt multiple rear material blocking shafts with more complete functions according to customer needs.

The hydraulic system adopts an integrated control system, which reduces the installation of pipelines, overcomes oil leakage, ensures the stability of the machine tool, and has a simple and beautiful appearance.

The hydraulic deflection automatic compensation mechanism eliminates the impact of slider deformation on workpiece quality, and the CNC system automatically adjusts the compensation amount, making it convenient and accurate.

The CNC system adopts specialized CNC systems for Dutch DELEM, Italian ESA, or Swiss CYBELEC electro-hydraulic servo bending machines.

|

|

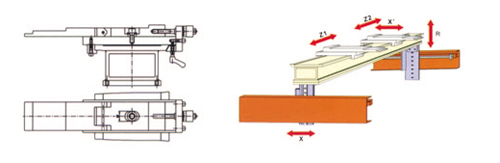

II(X、R)后挡料

II (X, R) rear blocking material

|

III(X、R、Z1、Z2后挡料

III (X, R, Z1, Z2 rear stop material) |

|

|

II型:2个数控轴(X、R)

2手动调节轴(Z1、Z2)

Type II: 2 CNC axes (X, R)

2 manual adjustment shafts (Z1, Z2)

|

III型:4个数控轴(X、R、Z1、Z2)

Ⅵ型:5个数控轴(X、R、Z1、Z2、H)

Type III: 4 CNC axes (X, R, Z1, Z2)

Type VI: 5 CNC axes (X, R, Z1, Z2, H)

|

|

|

|

|

高精度光栅尺安装于C型架上,克服了机身

变形对折弯精度的影响

The high-precision grating ruler is installed on the C-frame, overcoming the influence of body deformation on bending accuracy |

液压凸形油缸自动补偿系统,克服了滑块

变形对折弯精度的影响

The hydraulic convex cylinder automatic compensation system overcomes the influence of slider deformation on bending accuracy |

|

|

进口高品质伺服系统

性能介绍:

转矩控制、速度控制、位置控制三环一体;高速、高精度运转;频率响应高、整定时间短;自动调整内部增益;小体积、易操作、易接线

Imported high-quality servo system

Performance Introduction:

Integrated torque control, speed control, and position control; High speed and high-precision operation; High frequency response and short setting time; Automatically adjust internal gain; Small size, easy to operate, easy to wire |

|

|

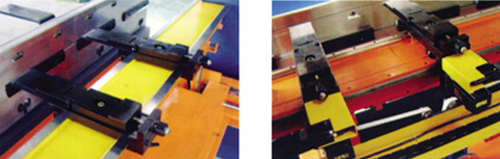

快速换模夹紧装置

Quick mold changing clamping device |

|

|

后挡料控制装置

简洁、稳定、可靠的后挡料控制,即简洁又大方

Rear material control device

Simple, stable, and reliable rear material control, both concise and elegant | |

|